Ultrafast lasers enable 3-D micropatterning of biocompatible hydrogels

September 28, 2015

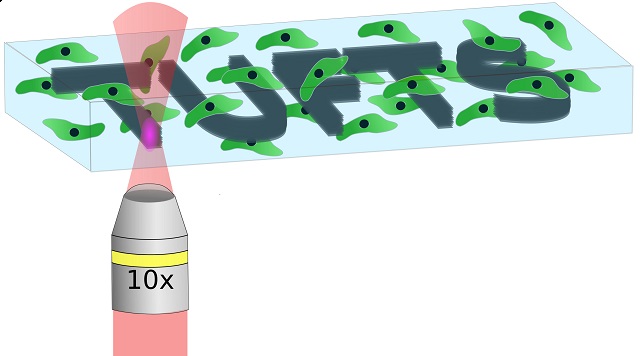

Illustration of laser-based micropatterning of silk hydrogels. The transparent gels enable the laser’s photons (pink) to be absorbed more than 10 times deeper than with other materials without damaging the cells (green) surrounding the letters (credit: M.B. A)

Tufts University biomedical engineers have developed low-energy, ultrafast laser technology for micropatterning high-resolution, 3-D structures in silk-protein hydrogels.

Micropatterning is used to bring oxygen and nutrients to rapidly proliferating cells in an engineered tissue scaffold. The goal is “to controllably guide cell growth and create an artificial vasculature (blood vessel system) within an already densely seeded silk hydrogel,” said Fiorenzo G. Omenetto, Ph.D., senior author of a paper on the work in PNAS Early Edition published September 15 online before print.

Current patterning techniques allow for the production of random, micrometer-scale pores and also the creation of larger channels that are hundreds of micrometers in diameter, but there is little in between.

The Tufts researchers used the ultrafast femtosecond laser to generate scalable, high-resolution 3-D pores (voids) within silk protein hydrogel, a soft, transparent biomaterial that supports cell growth and allows cells to penetrate deep within it. The researchers were able to create pores at multiple scales as small as 10 micrometers and as large at 400 micrometers over a large volume.

The transparent silk gels also enabled the laser’s photons to be absorbed nearly 1 cm below the surface of the gel — more than ten times deeper than with other materials — without damaging adjacent material.

The laser treatment can be done while keeping the cell culture sealed and sterile. Unlike most 3-D printing, this technique does not require photoinitiators (compounds that promote photoreactivity but are typically not biocompatible).

Omenetto is associate dean for research, professor of biomedical engineering and Frank C. Doble professor at Tufts School of Engineering and also holds an appointment in physics in the School of Arts and Sciences.

The research team reported similar results in vitro and in a preliminary in vivo study in mice.

Abstract of Laser-based three-dimensional multiscale micropatterning of biocompatible hydrogels for customized tissue engineering scaffolds

Light-induced material phase transitions enable the formation of shapes and patterns from the nano- to the macroscale. From lithographic techniques that enable high-density silicon circuit integration, to laser cutting and welding, light–matter interactions are pervasive in everyday materials fabrication and transformation. These noncontact patterning techniques are ideally suited to reshape soft materials of biological relevance. We present here the use of relatively low-energy (< 2 nJ) ultrafast laser pulses to generate 2D and 3D multiscale patterns in soft silk protein hydrogels without exogenous or chemical cross-linkers. We find that high-resolution features can be generated within bulk hydrogels through nearly 1 cm of material, which is 1.5 orders of magnitude deeper than other biocompatible materials. Examples illustrating the materials, results, and the performance of the machined geometries in vitro and in vivo are presented to demonstrate the versatility of the approach.